Method of the cross or method of the dots? And what, precisely, is a “grain of rice”?

Even though your central processing unit (CPU) is among the most fragile and expensive parts of your build, there is no need to freak out about applying thermal paste.

Bạn đang xem: How To Apply Thermal Paste Cpu Gpu Update 07/2024

How to apply thermal paste to your central processing unit (CPU) and graphics processing unit (GPU) is covered in detail here.

So What Is Thermal Paste? And Why Is It Important?

As the name implies, thermal paste is a conductive compound used to facilitate heat transfer between two surfaces (such as a heatsink and a CPU). Miniscule flaws in metal surfaces cause the formation of air bubbles upon compression.

Because air is such a terrible heat conductor, thermal paste is used to seal off any spaces between the components.

The stock fan that comes with most CPUs has already had a compound applied to it. While most users won’t need to replace this cooler, those who intend to overclock or who are seeking maximum performance from their system should.

For as little as $40, you can upgrade to a cooler that will keep your PC running quietly, dissipate heat more efficiently, and extend its lifespan.

How Does Thermal Paste Work?

Central processing units (CPUs) can become very hot, so it is important to quickly remove the heat they generate. Because air is such a poor heat conductor, it’s important to have as little of it as possible between the CPU and the heat sink for efficient transfer.

Anyone who has poked around the guts of a computer knows that the CPU is pressed up against the heat sink. Although a snug fit gives the impression that this seal will prevent air from entering, it is actually not effective.

A multitude of tiny grooves and gaps can be found on the CPU and the contact plate of the heat sink. These spaces, if not properly sealed, let air between the processor and the heat sink, decreasing the efficiency of the heat exchange.

It is at this point that thermal paste becomes useful. Thermal paste is a good heat conductor and can also fill in tiny crevices and divots on components. An airtight seal is formed, which expedites the heat transfer.

The thermal paste will age and dry out over time. The heat generated by the CPU is exacerbated by the dryness, reducing its efficiency. In order to keep a computer from overheating, it is recommended that the thermal paste be applied again.

Do You Need Thermal Paste?

It’s easy to overlook the importance of thermal paste in a PC build in favor of more obvious components like the CPU and power supply. A computer can start up without thermal paste, but it will be difficult to keep running.

Heat is not transferred efficiently between the CPU and the heat sink in the absence of thermal paste. Thus, the central processing unit (CPU) runs much hotter than if you had used paste. If the CPU is allowed to overheat, it will shut down unexpectedly, blue screen, and cause stuttering due to throttling.

Even though picking up some thermal paste is the least exciting part of putting together a new computer, it is essential. Your computer will be safer from overheating and shutting down thanks to the improved efficiency of the heat sink.

If you are unsure about whether or not you need thermal paste and are afraid of damaging your brand new, expensive processor with the gray goop, you should consider purchasing a heat sink that already has paste applied to it. Even if it isn’t the best paste available, it simplifies set up.

CPU Guide

Step 1: Prepare the CPU and Heatsink

Materials Required:

- Anisotropic Rub-On Agent

- Material that doesn’t attract lint

Most central processing units won’t need cleaning right after they’re unboxed. If you’re installing a new heatsink onto an already-existing processor, however, you’ll need to scrape off the old, dried thermal paste first.

Two-step cleaners are available online, but a high-percentage rubbing alcohol like 99% Isopropyl will do the trick as well.

Drop a small amount onto the outdated paste and let it sit for a while so that the compound can be broken down. Then use a lint-free cloth to remove the remaining residue. Do the same thing with the CPU’s heatsink until it, too, is clean.

Step 2: Apply the Paste

You Will Require:

- The thermal paste should be replaced with something else, like Artic MX-4 or Noctua NT H1 Thermal Compound.

The proper use of thermal paste is a topic of heated debate among PC enthusiasts. Some people are devoted to the dot method, while others favor the spiral approach.

In practice, however, the performance gap between these approaches is typically quite narrow.

Heatsinks are heavy enough that the compound will spread out evenly for you if you use a sufficient amount.

Since this is the case, we advise squeezing a pea-sized dot onto the center of your CPU. The heatsink should be installed afterward, using extreme caution. Don’t worry about dispersing it; doing so by hand runs the risk of introducing tiny air bubbles into the mixture that weren’t there before.

GPU Guide

Step 1: Open the Card

Materials Required:

- Screwdriver

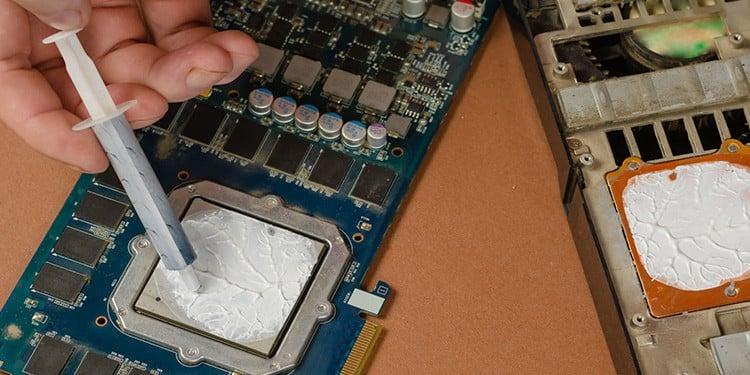

The process of replacing the thermal paste on your GPU is more involved than simply opening up your graphics card and applying new paste.

When opening a GPU, you’ll usually just need to loosen four screws around the processor, but on some models, you may need to remove even more to completely free the heatsink.

When you’ve unscrewed everything, give the cooler a little wiggle to make sure it’s completely free. If it is free to move, you can slowly pull it out of the way.

If there is still resistance, don’t try to force it and instead double-check for any missing screws. And be wary of the plug that powers your fan. This delicate link can be broken if you try to force open the card.

It’s possible that your GPU has thermal pads dispersed among its individual parts. Don’t take these off. You should not replace these pads unless you have spares that are an exact match.

Step 2: Remove Stock Paste

Equipment Necessary

- Alcohol for Rubbing

- Non-linting fabric

The stock thermal paste used by most GPU manufacturers is excessive, making this step sticky. To get rid of the dried thermal paste on the GPU, you can mix a small amount of rubbing alcohol with the old compound and then gently buff it off.

The heatsink cleanup is the messiest part. Saturate a new section of your lint-free cloth with rubbing alcohol. Carefully wipe away the excess paste. When most of the paste is removed, you can use a clean section of the cloth to gently wipe away what’s left.

Step 3: Apply the Paste

Things You’ll Have to Have on Hand

- Thermal paste replacement

Put a small amount of thermal paste, about the size of a pea, in the middle of your GPU. Don’t pass it around, once more. The pressure from reattaching the heatsink to the card will help spread the paste.

What’s the Best Thermal Paste Brand?

A good thermal paste is difficult to find because everyone has their own preferences. The best brands, however, can be selected by examining test results and making a decision based on the underlying data.

The effectiveness of thermal paste is evaluated by monitoring the system’s idle temperature. Next, thermal paste of a specific brand is applied to the CPU. The machine is then subjected to a battery of rigorous tests.

During a stress test, the maximum temperature the processor reaches is monitored. The temperature during the stress test is compared to the temperature during the previous period of inactivity. The effectiveness of the thermal paste in dissipating heat is measured by the margin of error between the idle temperature and the stress test temperature.

You can use this comparison sheet to find out which brands of thermal paste perform the best by selecting the compound that causes the least amount of heat to be transferred. If you’ve never used thermal paste before, the spreadsheet will indicate which brands are the most difficult to apply.

Type of Paste

There are many different kinds of thermal pastes, but the most common ones are made of carbon, ceramic, or liquid metal. However, liquid metal-based pastes are effective for heat dissipation but can be dangerous for inexperienced users to apply to CPU/GPU chips, making ceramic-based pastes the best and most preferred option for both new and experienced users.

Quantity

Every tube of thermal paste should have enough material to properly mount a CPU. The quantity of paste you need to install multiple processors should be taken into account before making your purchase. Since more installations can be done with a larger quantity of paste, some manufacturers have made paste with a larger capacity.

Thermal Conductivity

A thermal paste’s thermal conductivity is a measure of how efficiently it transfers heat from the CPU to the heatsink, where it can be dissipated. Watts per meter kelvin (W/mk) is the unit of measure for thermal conductivity. Simply put, the higher the value, the more heat the CPU will produce.

Read our comprehensive Buying Guide for more information on how to select the finest thermal paste for your needs. The same data was used to create a list of the best thermal pastes, complete with in-depth analyses of each option’s features, benefits, and drawbacks. Read them over to simplify your decision and ensure you end up with the best possible fit for your needs.

9 Best Thermal Paste for CPU/GPU in 2022

1. ARCTIC MX-4 Thermal Paste

Since Arctic sells thermal paste in a wide price range, it is a popular choice among consumers. The thermal paste in their MX series is among the most widely used because of its low price.

Since it has been a popular choice among previous users and is also relatively inexpensive, we have placed it near the top of our list of recommended thermal pastes. The MX-4 thermal paste from Arctic MX uses the company’s tried-and-true recipe to provide you with the industry-standard 8.9 W/mK thermal conductivity. Its superior heat dissipation capabilities make it a top pick for both central processing unit (CPU) and graphics processing unit (GPU) use. Avoid costly component replacement due to electrical current damage by using MX-4, which contains no metals and is electrically non-conductive.

Arctic MX-4 has a potential lifespan of over 8 years after a single application because it does not contain any metal or Silicon proportion, making it last longer than those that do. Because of its clever construction, MX-4 thermal paste stays at the perfect consistency and is simple for even inexperienced hands to apply.

![How To Apply Thermal Paste To A GPU Or CPU [2023 Guide]](https://gemaga.com/wp-content/uploads/2023/03/how-to-apply-thermal-paste-cpu-gpu-2.jpg)

Xem thêm : Getting A Javascript Error On Discord Update 07/2024

Highest Quality:

- Low-cost thermal paste

- We have 4 grams in stock.

- With a thermal conductivity of 5 W/mK

- Temperature range of operation is from -50 degrees Celsius to 110 degrees Celsius.

- About 8 years is the average lifespan.

- Compound devoid of metal and Silicone

Pros:

- Inspired by a tried-and-true Arctic recipe

- Consistently a top pick

- Exceptionally long life spans are to be expected.

Cons:

- However, the applicator is not included.

2. Noctua NT-H1 Thermal Paste

Noctua is a high-end manufacturer that specializes in cooling solutions for computers, including case fans, CPU coolers, and thermal pastes. The next option, also offered by Noctua, is a high-end favorite.

Noctua, our second choice, is another respected manufacturer. You can put your trust in the Noctua NT-H1 without giving much thought to its technical details, unlike any other option currently on the market. The thermal paste is of high quality and can be used with both CPUs and GPUs. The Noctua NT-H1 has been highly recommended and has won over 150 awards for its outstanding performance.

You can simply squirt the 3.5 gram syringe of Noctua NT-H1 over the top of your heat sink. In addition, the surface can be easily cleaned in the event of a mishap during application or when removing old thermal paste. Its high density means that it can be cleaned with just dry paper towels, and it doesn’t even need alcohol. The Noctua NT-H1 has a lifespan that is multiplied by ten thanks to its resistance to electricity and lack of corrosion. The performance of any leftover thermal paste can be reused for up to three years after it was first applied.

Superior Characteristics:

- There are 3.5 grams available.

- More than 150 commendations and honors

- Temperature range for use is between -50 and 110 degrees Celsius.

- Thermal paste of the highest caliber

- Protection from electricity and corrosion

- Three-year shelf life possible.

Pros:

- The optimum lifespan is 5 years.

- It has a wide range of potential uses.

- Can be stored indefinitely without deterioration

Cons:

- An undefined thermal conductivity

3. Arctic Silver 5 Thermal Paste

Another Arctic-themed special is here! Among the many products Arctic offers, silver thermal pastes are among the most reasonably priced options.

Our number three choice for the best thermal paste, made with a 99.9% pure micronized silver composition, offers excellent performance and dependability. There are 3.5 grams of Arctic Silver 5 paste in each container, and its thermal conductivity is 8.5 W/mK at room temperature. To top it all off, the paste is completely non-conductive electrically, which is crucial when using thermal paste on a computer. The thermal paste is dense and has a thick consistency, so it doesn’t bleed or deposit too much.

The thermal paste syringe’s string is constructed in such a way that it can be used to apply the paste without any additional tools. The leftover thermal paste can be kept in the same syringe until it’s needed again. For optimal performance, use Arctic Silver 5 thermal paste between -50 degrees Celsius and 130 degrees Celsius, as recommended by Arctic. Additionally, Silicon is not a part of Arctic Silver 5’s composition, which has many benefits.

the finest qualities:

- This thermal paste is one of the cheapest options available.

- The supply is currently 3.5 grams.

- Thermal conductivity of 5 W/mK

- The range of acceptable temperatures for operation is between -50 and 130 degrees Celsius.

- Totally resistant to the flow of electricity

- In every way, it’s Silicon-free

Pros:

- Use and storage are a breeze.

- Great if the temperature is just right

- Conventional thermal conductivity

Cons:

- There ought to have been a greater supply.

4. Nabob Deals Thermal Paste

Nabob deals is a unique option among the brands we’ve included here because it produces a wide variety of goods, not just thermal paste. However, many of its products have been purchased in the past to rave reviews from satisfied customers.

Almost 88% of the weight of the Arctic Silver 5 Thermal Cooling Compound from Nabob Deals is made up of thermally conductive filler. Other compounds, such as zinc oxide, aluminum oxide, and boron nitride, are present alongside micronized silver to increase its thermal conductivity even further. This one-of-a-kind, high-density product is easy to apply over crucial surfaces thanks to the dedicated thermal paste applicator and 3.5-gram syringe of thermal paste included in the Nabob Deals package.

The Nabob Deals Arctic Silver 5 provides excellent performance once installed thanks to its standard thermal conductivity level, which reduces the CPU temperature and thereby improves its performance. It appears that the performance has completely stabilized as the temperature has dropped. You can get many installations done with the same syringe if the layer of application is up to 0.003 inches thick for each application. Depending on how much you use, the temperature of your central processing unit (CPU) can drop by three to twelve degrees after application.

Features I Love the Most:

- Three and a half grams are at your disposal.

- Excellent efficiency.

- Includes a tool for precise application

- Filler that is 88% thermal conductor

- A decrease in temperature of 3 to 12 degrees is possible for CPUs.

- Comprised of silver, zinc oxide, aluminum oxide, and boron nitride

Pros:

- Excellent chemical make-up

- versatile enough to be used in a variety of contexts

- Compatible with central processing units and graphics processing units

Cons:

- Optimal temperature range is not specified.

5. Thermal Grizzly Thermal Paste

Next, we have Thermal Grizzly’s premium thermal paste, which is the best money can buy. This company is well-known for manufacturing high-quality goods, including the thermal paste discussed here.

If the quantity and thermal conductivity of thermal paste are your top priorities, look no further. Because of its high thermal conductivity (12.5 W/mK) and generous quantity (5.55 grams in each syringe), the Thermal Grizzly Kryonaut Thermal Paste is your best bet. Applications requiring temperatures between -250 degrees Celsius and 350 degrees Celsius will find this thermal conductivity range to be ideal.

In cases where you intend to overclock your CPU or graphics card after the build is complete, this option is preferable due to the wide temperature range within which it can operate. Stable performance after overclocking is possible thanks to Thermal Grizzly Kryonaut Thermal Paste’s ability to maintain low temperatures even when hardware is running at increased speeds. With no cure time and excellent long-term stability, Thermal Grizzly Kryonaut Thermal Paste can be used immediately or stored for long periods of time.

Top-Rated Attributes:

- Top-tier thermal paste

- Created specifically for use with computers that have had their clock speeds increased

- The quantity available is 5.55 grams.

- Thermal conductivity of 5 W/mK

- In order for it to function, the temperature must be between -250 and 350 degrees Celsius.

- The top pick for always-on infrastructures

Pros:

- With one of the highest thermal conductivities on the market

- The quantity included is greater than any other

- Consistent with long-term use

Cons:

- Thermal paste comes at a high price.

6. SYY Thermal Paste

All thermal pastes are not created equal, and not all of them are designed for use in gaming and working computers. There are only a select few companies, such as SYY, that produce industrial-strength thermal pastes for use in mission-critical systems.

As a conclusion, we have set aside the highest rated thermal paste on our list. With a thermal conductivity of up to 15.7 W/mK, the SYY thermal paste opens up a wide range of new possibilities. Because of its high temperature range, from -30 degrees Celsius to 280 degrees Celsius, it can be used in situations where regular thermal pastes would fail. Additionally, it is a thermal paste that contains no metals and is electrically non-conductive, protecting against the risk of short circuits and other similar issues.

SYY thermal paste outperforms liquid metal, the gold standard for high-performance thermal transfer, thanks to its superior thermal conductivity. Another huge plus is that it can be purchased for less than half the price of high-end thermal paste. Newcomers who are working with thermal paste for the first time will appreciate the inclusion of a dedicated paste applicator from SYY alongside the 2 gram syringe.

Excellent Characteristics:

- Compound thermal paste with specific applications

- Free of metal and not conductive to electricity

- Included is a tool for applying paste.

- There are 2 grams available.

- Thermal conductivity of 7 W/mK

- The usable range of temperatures is from -30 degrees to 280 degrees Celsius.

Pros:

- maximum thermal conductivity

- The combination of high performance and solidity is delivered.

- Great if the temperature is just right

Cons:

- Very few in number

7. Flux Thermal Paste

It is not necessary to invest heavily in high-end thermal paste if you intend to use it for non-critical purposes. FLUX, on the other hand, is a great brand that won’t break the bank.

We’ll start with the most expensive thermal paste on our list and work our way down to the cheapest option. When compared to today’s high-end options, the FLUX Thermal Paste is a steal. Additionally, FlUX provides 5 syringes per package, allowing for multiple injections without the need for extra space. Each syringe contains 1.5 grams of thermal paste, and the paste’s thermal conductivity is about 3.2 W/mK.

The Flux Thermal Paste requires no special preparation before application; simply open a syringe and spread the paste directly onto the heatsink. Polysynthetic grease is used to make the paste, which improves its effectiveness. It’s a fantastic option for central processing units and graphics processing units, especially if you have a number of computers at home or in the workplace.

Xem thêm : Getting A Javascript Error On Discord Update 07/2024

Highest Quality:

- Thermal paste with the lowest price tag

- 1.5 grams per syringe is the current supply.

- Thermal conductivity of 2 W/mK

- Each package contains 5 different syringes.

- Plaster of silver, polymer, synthetic grease

- Simple to implement in a variety of contexts

Pros:

- The thermal paste has been pre-divided for simple use.

- Lightweight and simple to put away

- Sound composition

Cons:

- Very low thermal conductivity

8. GELID GC-Extreme Thermal Paste

We recommend these alternatives to Gelid because they are more well-known among consumers. Yet, if you’re looking for a commercial-grade thermal paste at a reasonable price, this is a fantastic brand to consider.

The GELID GC-Extreme thermal paste is superior to standard thermal pastes in terms of conductivity and is intended for use in demanding environments. You’ll get 3.5 grams of paste with a thermal conductivity of 8.5 W/mK from one of these tubes. GELID GC-Extreme’s high conductivity ensures it will outperform all other options at this price point. At the time of overclocking, it will also provide your CPU with the stability it desperately needs.

An exclusive GELID applicator is included for simple thermal paste application on any substrate. GELID GC-Extreme’s high thermal conductivity allows for use in temperatures ranging from -45 degrees Celsius to 180 degrees Celsius, making it a versatile material. Keep in mind that, presently, there is no other option on the market that can compete with the temperature range offered by this thermal paste.

Unique Characteristics:

- Thermal compound for extreme use

- Good for use in data centers and with cryptocurrency mining hardware

- The supply is currently 3.5 grams.

- Warmth transfer at 5 W/mK

- temperature range of -45 degrees to 180 degrees

- With the applicator, it’s a breeze to put on.

Pros:

- Compatible with specialized machinery

- The optimal operating temperature range for this category is

- The low paste density of 73g/cm2 facilitates assembly.

Cons:

- Ideally, there would have been a greater supply.

9. LANSH Arctic Silver Thermal Paste

An additional Arctic thermal paste is included in the lineup. This package comes with Arctic’s toughest thermal paste yet, made specifically for industrial use.

In terms of thermal conductivity and user friendliness, the Arctic Silver thermal paste that is recommended here is among the best thermal pastes available on the market. The Arctic Silver thermal paste has a high thermal conductivity of 9 W/mK, making it suitable for both home and professional use. Arctic has specified a temperature range of -50 degrees Celsius to 130 degrees Celsius, which should be suitable for a wide variety of uses.

Arctic Silver thermal paste is made of high-density micronized silver and conductive ceramic particles that were added to the paste to increase thermal conductivity without adding any electrical conductivity. As its triple-phase viscosity can be controlled, this paste facilitates installation. As a result, your system will maintain a rock-solid foundation, even when subjected to sustained, high-volume workloads.

Top-Rated Attributes:

- Arctic region’s most potent thermal paste

- 3.0 grams are currently in stock.

- In terms of temperature, the thermal conductivity is 9 W/mK.

- The range of acceptable temperatures for use is from -50 degrees to 130 degrees Celsius.

- Tiny ceramic particles are embedded in a silver paste that has been micronized.

- Viscosity in three phases

Pros:

- Equilibrium will be restored to the system.

- Nonconductive to electricity in every way

- Superb thermal conductivity

Cons:

- There is a strict quota on this item.

How to Choose the Best Thermal Paste:

There is a wide variety of thermal pastes available, and you should know that they are not interchangeable. Heat dissipation from this paste is temporary, lasting at most a few years before it needs to be reapplied.

It can be challenging to choose the best option from the above list. We’ve put together this guide to assist you in making the most informed purchase possible.

Let’s dive deeper into what to look out for and why when purchasing thermal paste.

1. Types:

In the future, the quality of thermal paste you choose will have a greater impact on how well it performs. It needs to be the right fit for your PC and your level of experience with this paste. Although liquid-metal pastes are effective heat dissipaters, they should be avoided by inexperienced or novice users.

Liquid-metal paste solutions typically contain electrically conductive metallic bits, and even a single drop spilled onto the processor pins will immediately render them useless. A thorough cleaning of spills on the motherboard may still cause the damage, however, and will therefore void your product warranty. It is, therefore, highly risky to use on the central processing unit.

A ceramic-based paste in either grey or white, created by combining silicone paste and ceramic powder, is the best option for beginners. The use of these non-conductive compounds makes their application much safer than that of metal pastes. Therefore, it is a viable alternative to the metal paste for everyone.

2. Heat Transfer or Thermal Conductivity:

Thermal conductivity is defined as the ability to transfer heat from one location to another. When working with computers, thermal paste is spread between the central processing unit (CPU) and the heatsink to transfer heat from the CPU to the heatsink as quickly as possible.

The thermal conductivity of the paste is measured in watts per meter Kelvin (W/mk). Higher values improve heat dissipation (they remove more heat from the GPU/CPU). So, paste with a conductivity of 38 W/mk is superior to paste with a conductivity of 12.5 W/mk. Any reputable thermal paste product will get the job done, but the actual temperature difference between one product and another may be a few degrees ( /-), depending on the components and cooling system you use.

Consequently, despite the high price, it is preferable to buying the thermal paste with a higher thermal conductivity rating.

3. Quantity:

Each tube of CPU paste typically contains enough to mount a CPU on a motherboard. If you only plan on using this paste on one or two processors, you don’t need to worry about the quantity. However, before purchasing this paste, you should verify the quantity (amount) while performing multiple installations. Only a select few manufacturers sell their wares in sufficient quantity to allow for additional installations.

So, if you need the paste for multiple installations, go with a larger tube, and if you only need it once, go with a smaller tube (like 1.5 g).

There should be enough space in the package to safely store the thermal paste if you purchase more than you can use immediately. Keep the thermal paste in the syringe it came in, sealed in a airtight container. Having more than one syringe on hand is helpful in these circumstances because only one can be opened at a time.

4. Thermal Paste Lifespan:

After being applied, the lifespan of each paste will vary greatly, and their effectiveness will be limited to a window of roughly two to eight years. Simply put, low-end models may require paste replacement every 2–3 years, while high-end models typically last for 8 years before needing to be replaced. Even if the original state deteriorates over the course of three years, the low-end paste can usually still provide better performance.

5. Ease of Installation & Viscosity:

Some thermal pastes are made to be applied more easily than others, despite the risk of electrical conductivity. Knowing the thermal paste’s viscosity is important for any builder, whether novice or seasoned, as it ensures that no extra paste is squeezed out.

However, the method of application differs greatly depending on whether a thick or thin paste is used. Thinner paste is much easier to apply, but thicker paste is notoriously difficult to work with. So, to apply them correctly, it is important to think about the thickness of the paste you brought.

6. Delivery Method:

You can get thermal paste in a tub, a syringe, or a tube. Either kind of paste can be used, so it’s up to you to decide which one to check out and buy.

Tubes are cheap, but they’re not precise, and if you’re not careful, you’ll end up with more paste than you bargained for. It’s like trying to use an almost empty tube of toothpaste: it’s a pain.

When it comes to tool-based tasks, the best and most expensive option is tubs, which are available in large quantities and serve multiple purposes.

Injecting substances with a syringe is the most common and least expensive method, and it is also very precise. Many professionals advise using this method because it allows for more precise application of paste and greater control over the desired amount.

7. Thermal Paste Compound:

A significant contribution to the paste’s durability and effectiveness can be attributed to this chemical component. This thermal paste is typically manufactured by various brands using a variety of chemicals to achieve a predetermined level of thermal conductivity. Before buying thermal paste, it’s a good idea to read reviews written by people who have already used it. This will give you an idea of the paste’s usability and durability.

Also, check the thermal paste’s ingredients to make sure no harmful or potentially dangerous ingredients were used to make it. The ideal thermal paste compound would have good thermal conductivity but no electrical conductivity.

8. Price:

Don’t try to save money on the thermal paste because we already spent a lot of money on the processor. If you want to overclock, the performance of your machine is affected by the thermal paste you use. You can find thermal pastes like these for under twenty dollars.

Frequently Asked Questions:

1. What is the difference between thermal paste and adhesives?

Heatsink compound, thermal grease, thermal gel, thermal compound, and thermal paste are all names for the same thing. However, the thermal adhesive is not like that at all. The thermally conductive glue used to make the adhesive pads ensures a secure connection between the CPU and heatsink.

They’re less effective than thermal pastes but easier to apply, messier, and more forgiving of human error. They function similarly to thermal pastes in that they keep working until the GPU or CPU is operating at overclocked speeds or at stock frequencies, whichever comes first.

2. What is the maximum lifespan of thermal paste?

The user must be aware of how long the paste lasts before it must be replaced. Not only do most of these become solid and lose their conductivity over time, but they also won’t come with a quick expiration date. Consequently, it is recommended by most manufacturers that they be replaced every 3–5 years.

There is no need to reapply thermal compound or replace it for many years of use unless you are an extreme gamer or overclocker. Thus, replacing the thermal paste each time the GPU/CPU heatsink is removed is a necessary part of long-term practice/use of the system.

3. What happens if I use too much thermal paste?

Excessive use of paste is not recommended. Almost without exception, the thermal paste recommended by CPU and GPU manufacturers is the size of a pea. However, if you use too much thermal paste, there will be chunks of paste preventing adequate contact between the heatsink and CPU. Overfilling the CPU socket will cause it to leak all over the CPU’s edges, the socket cover, and the motherboard. The little bit of extra won’t hurt anything if it doesn’t touch the motherboard.

Too much paste turns into an insulator, and using an electrically conductive paste could cause a short in the computer. The reduced effectiveness of the thermal paste could lead to a decrease in the overall thermal conductivity, increasing the risk of overheating. In addition, it’s not simple to remove the buildup of gunk from a CPU socket without damaging the pins.

4. How to apply the thermal paste and remove it?

Here are the procedures to follow when installing and removing thermal paste from the central processing unit and graphics processing unit.

The CPU must be positioned precisely in its socket on the motherboard before the paste can be applied. Put a tiny amount of thermal paste (smaller than a pea) in the middle of the central processing unit. Next, place the part where indicated by the dot and press down firmly to secure it. The thermal paste is applied, and the component is checked by lifting it once. We can mop it up and try again if it’s not done right.

See our article “How to Apply Thermal Paste” for details.

To get rid of the paste without creating more microscopic holes that would allow heat to escape, wipe it off with a microfiber cloth or a coffee filter. Thermal paste can be cleaned effectively with a microfiber cloth and some rubbing alcohol. In this case, either ethyl or isopropyl alcohol would work as the rubbing alcohol. It is recommended by most thermal paste manufacturers and central processing unit/graphics processing unit manufacturers that a higher concentration of isopropyl alcohol be used to remove residue from thermal paste.

In order to learn more about removing the residue left behind by the thermal paste on your CPU, please refer to our detailed guide on the subject.

5. Does thermal paste fix overheating? Can old thermal paste cause overheat?

By sealing all of the crevices between the CPU and the cooler with thermal paste, you can rest assured that heat is being transferred efficiently and that the CPU will not overheat. However, you shouldn’t put all your faith in the thermal paste to prevent them from heating up. This multi-pronged setting will reduce the current temperature and fix overheating by ensuring that the fan is in good working order and has been regularly maintained.

Thermal paste has a limited shelf life (typically between 3 and 5 years), after which it should be replaced for optimal thermal conductivity. Overheating of the CPU occurs when old thermal paste is used because it fails to transfer heat effectively from the CPU to the heatsink.

6. Do we use any thermal paste on the CPU?

To get the best results from stress testing software or overclocked systems, you can use thermal adhesives or pastes from any reputable brand. Many different types of thermal paste exist, each with its own optimal use case for dissipating surplus heat. Verify the quantity and technique used when applying the paste to the CPU. So, before you go slathering thermal paste all over your new PC, make sure you know what you’re doing.

7. Is it safe to run a CPU or GPU without thermal paste?

When applied to an integrated circuit’s surface, thermal paste helps to dissipate heat by filling any air gaps between the heatsink and the IC. Here, the processor’s heat is transferred to the heatsink, where it can be dissipated more quickly and effectively. Without thermal paste, heat transfer is impeded because air is used to fill the gaps between the processor’s heat sink and the motherboard. As a result, the computer or PC overheats, which triggers thermal throttling and shortens its lifespan.

8. What is the recommended quantity of thermal paste to apply to the PC?

In order to keep the CPU from overheating, thermal paste is required for PC gaming. This paste can be applied in a variety of ways, resulting in a coating that is as thin as paper over the central processing unit (CPU). A small amount of paste applied to each side will do the trick.

9. Does the thermal paste gets expired or go bad?

When using thermal paste, it’s important that the paste not be too thick or too runny, but rather that it retain its original texture, consistency, and color. The paste will quickly go bad if exposed to high levels of dryness, heat, oxidation, or humidity, so keep it out of direct sunlight or other extremely hot environments. Because of the importance of preventing the paste from coming into contact with air, it is typically sold in syringes rather than tubes. Please do not re-pull the paste through the plunger after using the syringe, as this will introduce air into the syringe and ruin the paste.

10. Which thermal paste is good for laptops?

Multiple brands of thermal paste are available for use with central processing units and graphics processing units in desktop and portable computers. The ProlimaTech PK-3 Nano Aluminum, Arctic MX-5, Thermal Grizzly Kryonaut, Noctua NT-H1, Cooler Master MasterGel Pro V2, and Gelid GC-Extreme are just a few examples of high-quality laptop thermal pastes.

11. What can I use if I don’t have thermal paste?

Thermal paste is a compound that can be applied to the GPU, CPU, and other electronic components to improve their thermal conductivity. Hold off on the PC build or upgrade until you can get your hands on some thermal paste. However, you can use a mixture of toothpaste and Vaseline (80:20) if you’re in a pinch. Fine aluminum powder combined with Vaseline is another option.

12. Is it worth buying thermal paste?

Adding new Thermal Paste to the CPU and GPU is one of the most fundamental tasks involved in building a new PC, upgrading an old PC with a new CPU, or maintaining a laptop or desktop computer. Even though most CPU coolers already include thermal paste, it is recommended that you use your own paste, preferably from a higher-quality brand, when building a new computer system. The CPU’s temperature can be maintained at a manageable level with the help of a good thermal paste, which facilitates heat transfer to the cooler or heat sink.

13. Can I use toothpaste as thermal paste?

To improve heat transfer between the central processing unit and the heatsink, Thermal Paste is used. Thermal pastes can be found in a variety of brands, and some of the better ones are available for a surprisingly low price. Instead of using tooth paste, which could damage your components, use thermal paste designed for this purpose.

14. How much thermal paste should I use on my CPU?

A small amount of thermal paste, about the size of a pea, should be spread across the middle of the central processing unit (CPU). You can just let the heat sink do the work of spreading the paste evenly across its surface. Doing so will guarantee a consistent application and prevent the paste from overflowing.

15. How often should I replace thermal paste?

However, thermal paste is not something that needs to be changed out frequently. Correctly applied thermal paste has a long lifespan (years, if not decades). If you do see an increase in CPU temperatures, however, it is best to replace the thermal paste and clean the fans and vents thoroughly.

16. Can we make thermal paste at home?

As the name implies, thermal paste is a chemical compound developed to improve the thermal conductivity of central processing units, graphics processing units, and other electronic components. Some thermal paste can be made with common household items and stored for use in an emergency. Mixtures of tooth paste and Vaseline, cocoa and hazelnut cream, and aluminum powder and Vaseline are all examples of such methods. If you want to keep your computer running smoothly, you need to invest in some thermal paste, even if it’s just a cheap one.

17. What happens if I use too much thermal paste?

Most central processing unit (CPU) and graphics processing unit (GPU) makers recommend using a “pea-sized” amount of thermal paste. On the other hand, if you use too much thermal paste, there will be clumps of thermal paste that prevent the CPU and heatsink from making good contact. Therefore, the overall thermal conductivity may drop if the thermal paste is ineffective.

18. What happens if you don’t apply thermal paste?

When you don’t use thermal paste, the air between the CPU and heatsink is just filled with air, and air is a terrible heat conductor. The temperature of the CPU will increase as a result of reduced heat transfer to the heatsink. The result will be thermal throttling, in which the CPU deliberately reduces its performance in response to rising temperature. When operating at excessively high temperatures, a computer’s central processing unit (CPU) will wear out much faster than usual.

19. Should I remove old thermal paste?

It is important to remove and clean the old thermal paste before applying new thermal paste. Never apply a new layer of thermal paste over an existing layer; the old paste is likely dried out and won’t provide any benefit to the new layer.

20. Can old thermal paste cause overheating?

For improved thermal conductivity, you should replace your thermal paste every few years (typically every three to four years). If you keep using old thermal paste, your CPU will overheat because the heat isn’t being transferred effectively to the heatsink.

21. What can I use to clean thermal paste?

To remove thermal paste’s residue, try using rubbing alcohol with a microfiber cloth. Either isopropyl or ethyl alcohol can be used as rubbing alcohol. To clean thermal paste, however, a higher concentration of isopropyl alcohol is recommended by most thermal paste manufacturers and CPU/GPU producers.

Conclusion

And you’ve accomplished it!

There has been a breakthrough in the application of thermal paste to central processing units and graphics processing units. The procedure is less complicated and easier to complete than it first appears.

Thermal paste upgrades can give a stale GPU new life and get a CPU ready for overclocking. Moreover, if you take the aforementioned measures, you will undoubtedly notice a reduction in both idle and load temperatures.

Nguồn: https://gemaga.com

Danh mục: Blog